EMBROIDERY

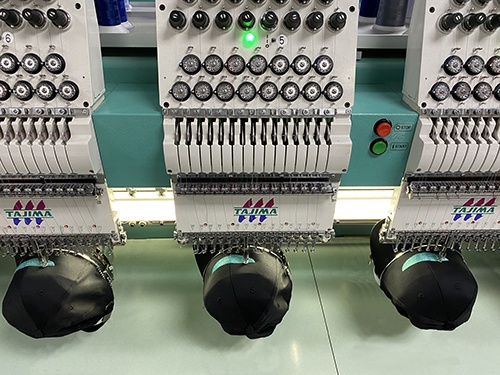

Using the top of the line Tajima Embroidery machines that can sew a wide selection of custom products, Screen Pro Graphics houses 41 heads of embroidery and has multiple shift capacity available to accommodate virtually any size request. Every quality embroidery starts with the right kind of artwork that we convert into a pattern of various stitch types to achieve the look of the design using thread. This conversion process is called digitizing. The precision of how a logo sews depends on the accuracy of the design set up and digitizing. We take the necessary steps to make recommendations in order to convert your design to sew out a beautiful product that showcases your brand in the best way.

Embroidery allows you the freedom to mix and match garment styles and colors on any order using the same logo. We can also change out thread colors within the same order for a fully customized product mix. The flexibility of these embroidery options creates the ultimate solution when it comes to tailoring your order to look amazing.

Embroidery Is Recommended For:

Polo Shirts

Golf Shirts

Pique Knits

Woven Button Downs

Jackets

Hats

Headwear

Blankets

Bags

Towels

And much more…

Screen Pro Graphics provides embroidery services to a variety of organizations such as Schools, Sports Teams, Businesses, Churches and City Programs right down to the local entrepreneur launching his or her own custom clothing line.

As one of the few authorized decorators for both The NorthFace® and Under Armour®, we pride ourselves on delivering the highest-quality embroidery possible.

Embroidery & Digitizing Is Priced By:

Style or Product Type

Stitch Count

Number & Type of Embroidered locations

EMBROIDERY METHODS & THREAD OPTIONS

Logo Embroidery

With custom embroidery you can give your logo a colorful, durable and professional look using a wide range of colors, details & textures! We digitize your logo and produce a realistic sew out of the finished art file for your approval before production.

Flat Stitch Embroidery

Flat Stitching is the industry standard for most common Embroidery requests. The key is in the digitizing! We aim for a clean & crisp finished product and always do our best to use the most effective stitch patterns & fills for a high-quality decoration result.

3D Puff Embroidery

Puff or 3D Foam Embroidery is one of the fastest growing trends in custom headwear embroidery! Puff embroidery is essentially foam filled embroidered letters & shapes that create a raised or 3D look. Combine both Flat & 3D Puff embroidery to enhance the focal point of your logo and make it pop on hats & custom headwear. For the best result, we recommend this primarily for simple & larger text and designs.

Personalization

Add custom personalization to any embroidered product! From traditional fonts to custom script lettering, we can embroider your name, title or rank to your custom uniforms & workwear. We can add custom personalization’s to bags, towels & other accessories for a completely customized look.

Stitch Patterns

- Satin Stitch – One of the three most common embroidery stitches used to produce an embroidery design, they are typically used for lettering and outlining. Formed by closely arranged zigzag stitches, the satin stitch can be laid down at any angle and with varying stitch lengths. Satin stitches can range in width from 1.5 mm to 8 mm; however, the wider the satin stitch, the more susceptible they are to snagging and abrasion.

- Zig-Zag – The zig-zig stitch is variant geometry of the lockstitch that creates a zig zag pattern. It is a back-and-forth stitch used where a straight stitch will not suffice, such as achieving a decorative look or a specific shape in an embroidered design. The satin stitch is essentially closely arranged zig zag stitches.

- Tatami or Fill Stitch – These are a series of running stitches used to cover large areas. Different fill patterns can be created by varying the length, angle or repeating sequence of the stitches.

- Program Split – This means you can stitch out embroidery designs that are larger than can be accommodated within a single hoop. The aim is to add hoops and move them around until you get the least number of hoopings necessary to accommodate the entire design. These are then stitched out consecutively.

- Jagged Edge – Creates poor quality lettering where the text is not sharp and crisp and has jagged edges. This issue generally can be corrected by:

- Digitizing properly

- Using appropriate stitch selection

- Outlining letter with running stitch

- Using underlay stitches

- Filling in with satin stitches

- Using proper stitch density

- Using short stitches at corners

- Using Topping

- Run Stitch – These are made when a single stitch is formed between two points used for outlining, underlay, and fine detail. Also known as a running stitch or walk stitch.

- Knockdown or Underlay Stitch – Stitches in a design that are put down before the design stitches, which are used to stabilize the fabric or raise the design so that the fine detailing is not lost in thicker fabrics like beanies and items with nap such as blankets and towels.

Most Common Stitches

Fill, Satin & Run Stitches are some of the most practical stitches for custom embroidery. 3D Puff Embroidery uses a Satin stitch with a foam filler beneath the thread. Fill Stitches are generally the most common way to fill in larger solid areas of the design.

Madeira Polyneon

Madeira’s 100% polyester machine embroidery thread, Polyneon is constructed of a specially developed raw material which eliminates looping, puckering and virtually all thread breaks. Suitable for almost any embroidered application, Polyneon’s unique formula makes this thread extremely durable and smooth running. Vibrant colors are glossy, shiny, as well as resistant to chlorine bleach, making Polyneon the ideal thread for embroidering on uniforms, safety garments and commercial linens.

Madeira Specialty Threads

Viscose, polyester and metallic threads are appreciated for their unique shine and look. However, to value them even more, we have machine embroidery threads to support their beauty by creating contrasts and their own style at the same time. FROSTED MATT is a matte-finish thread that does not reflect the light, which gives this thread an unrivalled look and makes your design a real eye-catcher. Alternatively, you can go completely in the opposite direction by using a transparent or glow-in-the-dark thread.

HAT EMBROIDERY LOCATIONS

HAT FRONT

RIGHT PANEL

LEFT PANEL

BACK LEFT PANEL

BACK RIGHT PANEL

RIGHT SIDE

LEFT SIDE

HAT BACK

EMBROIDERY LOCATIONS SIZES FOR HATS

FRONT

5″ Wide x 2″ Tall

PANEL

2.5″ Wide x 2″ Tall

SIDE

2.5″ Wide x 2″ Tall

BACK

4″ Wide x 1.5″ Tall

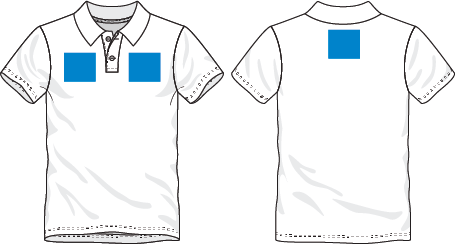

EMBROIDERY LOCATIONS

LEFT & RIGHT CHEST

YOKE

LEFT & RIGHT SLEEVE

BACK

COLLAR

LEFT & RIGHT HIP

EMBROIDERY LOCATIONS SIZES FOR POLOS

LEFT & RIGHT CHEST

3.5″ Wide x 3.5″ Tall

YOKE

3.5″ Wide x 3.5″ Tall

SLEEVES

3.5″ Wide x 3.5″ Tall

FAQ

What is digitizing?

Digitizing is the process of converting artwork or photography, such as a logo or design, into a stitch file that the embroidery machine can read and then sew out on your garment. Digitizing is equal parts art and science requiring a skilled digitizer to place the series of stitches in a way that brings your logo to life using thread. Yielding a high-quality product requires a digitizer to create this stitch file by hand, instead of using an auto digitizing software that generates really low-quality results.

Are there limitations on designs or logos that can be created in embroidery thread?

Yes! Because the design elements are created using thread, there are limitations to what we can create – a few of those limitations include small lettering, gradients, drop shadows and photographs. If you send in your art, we can let you know what restrictions may apply to your design or if it does not translate well into thread. Because we are using needles and thread, some simplifications must be made for a high-quality product. Or if you prefer, we can recommend an application that works best for your needs.

Can you use my EMB or DST file?

Yes! We can use customer supplied embroidery files (in EMB or DST formats). However, we recommend doing a sew-out prior to production. If there are quality concerns, we will reach out with recommendations and costs for redigitizing or editing to ensure a quality sew-out on the final product. The NorthFace® and Under Armour® products require in-house digitizing in order for us to quality control the embroidery from beginning to end.

How do I prep the files for embroidery?

All files must be a vector file or at least 300 dpi photo files at actual embroidery size. Preferred file types are AI, PDF, EPS, TIF, or PSD. Orders cannot begin until we have usable artwork.

Can you embroider on The NorthFace® & UnderArmour® brand merchandise?

Yes! As an approved decorator for The NorthFace® & UnderArmour®, we have several additional protocols and restrictions to follow when decorating these goods. Per our price sheet, there is a one-time $25.00 per logo set-up charge specifically for The NorthFace® or UnderArmour® goods. These brands must approve every logo that we decorate on their merchandise, since they have specific restrictions. Additionally, we require in-house digitizing for The NorthFace® & Under Armour® goods in order to have the ability to quality control the finished product from the beginning. There is also no spoilage offered.

Can you match my PMS Color?

We cannot guarantee exact PMS (Pantone Matching System) color matching in embroidery thread. Because Madeira makes a limited quantity of thread colors, we can help you find the closest match to your PMS color in our standard Polyneon Madeira thread colors.

Can I use my logo from a polo order to run on my hat order or my logo from a hat order to run a polo?

Unfortunately, a polo (also known as a flat) embroidery file does not run correctly on hats. Hat embroidery must be digitized in a specific way with the threads sequenced to sew in a precise direction. However, we can usually use a hat embroidery file on a polo. We would always recommend that you get both file types digitized when doing embroidery: one for hats and one for flats. Because of the wide variety of materials available in today’s marketplace, we may need to edit or redo your embroidery file in order to deliver the high-quality end product that our clients have come to expect from us.

Can you create patch-look embroidery or embroidered patches?

Yes! We have several solutions for creating embroidered patches or embroidering directly on a garment with a patch-look design. From heat applied embroidered patches, to direct path-style embroidery, we can handle almost any embroidery need. Contact us with the specifications and art for your project, and we can create a custom solution that works best for you.

Why do you have spoilage or underruns?

In custom manufacturing, such as embroidering customer supplied goods, minor fluctuations in the final number of units produced against the exact quantity ordered can occur. At Screen Pro Graphics, all orders can have up to 2% spoilage allowance or underrun. This accounts for manufacturer defects such as snags, stains, holes or damaged goods. Additionally, minimal damages can occur during any mass production process due to needle breaks, thread bird nesting, or variance in the way a machine runs.

Due to the nature of this business, we cannot be held responsible for shortages under the 2% threshold. The decoration cost for all damages or defects are credited upon invoicing. We recommend ordering extra goods if your project requires exact quantities. We have the capability of returning undecorated extras to the supplier, if necessary. Among promotional product suppliers, the industry standard for overruns and underruns allows for a + or – 5% discrepancy, which our 2% policy remains well under. We cannot offer any spoilage allowance on The NorthFace® and Under Armour® products as an authorized decorator for both brands.

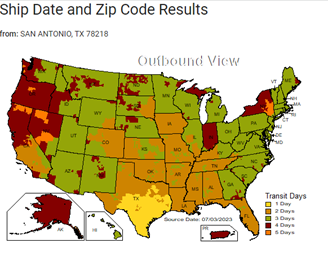

What is your turnaround time for embroidery?

Typical turnaround time is 7 to 10 days from the date of art approval and all merchandise must be received in-house.

We can accommodate rush orders for projects with lead times less than our 7-day turnaround, however a rush fee may apply depending on our current workflow. Rush services require approval from the customer service department, and depend on production schedule, quantity, item type(s), stitch count(s), and decoration location(s). (Taking longer than 24 hours to approve your digital proofs may delay your order.)

Can you provide RUSH services?

Yes! We can accommodate rush orders for projects with lead times less than our 7-day turnaround, however a rush fee may apply depending on our current workflow. Rush services require approval from the customer service department, and depend on production schedule, quantity, item type(s), stitch count(s), and decoration location(s). (Taking longer than 24 hours to approve your digital proofs may delay your order.)

We encourage you to let us know how we can help you bring your vision to life. Whether through our unique specialty thread options, in-house creative art department, high quality digitizing, or top-quality embroidery production, our world-class customer service team is here to guide you to the perfect custom printing solution. The better you express your overall vision and goal of the finished garment, the better we can fulfill or exceed your expectations. We encourage your input, so we know what you and your client(s) want to achieve in order to deliver 100% customer satisfaction.