SCREEN PRINTING

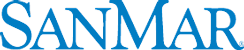

Screen Pro Graphics can handle all your screen printing needs in our 15,000 plus square foot facility. We have five presses going from a 6-color all the way up to our 14-color M&R Challenger 3 to tackle any size job required. We take your deadlines very seriously, and our production team understands the need for quick turnarounds. We have multi-shift printing capacity and our warehouse can comfortably house over 100,000 shirts, so no job is too big or too small.

As an environmentally conscientious company, we have chosen to align ourselves with WilflexTM Epic Rio brand inks, the leading manufacturer of plastisol-based ink in the screen printing industry. These inks are the most advanced non-phthalate plastisol inks that conform to all shipping regulations nationwide. We can match any pantone (PMS) color with our Color Mixing System and we offer FREE pantone color matching. With a wide range of specialty inks and processes, we can handle all your specialty printing needs.

Screen printing derives its name from the use of screens that are made of finely woven mesh stretched over a frame. We cover the area of the screen in non-permeable emulsion to form a type of negative image stencil for each color in a design. We then apply the ink to the screen, and the squeegee pushes the ink through the open spaces in the screen transferring the ink onto the garment when it travels across from the top to the bottom.

With our state-of-the-art M&R Challenger 3, we have the capability to screen print even the most detailed jobs with up to 12 colors in a single design. For extremely colorful artwork exceeding 12 colors, we typically use a simulated process, also known as a 4-color process, print method to achieve a higher color count. This method mixes 4 colors (CMYK) to create most colors in the spectrum. This 4-color process has been tested to best perform on white HD shirts. We recommended using Fruit of Loom HD shirts for the best results.

SPOT COLOR

Individual Solid Colors

PROCESS COLOR

A Blending of 4 Colors (CMYK) Using Overlapping Halftones

HALFTONES

A way to simulate shading, gradients, or blends by using a dot pattern

If you have full-color artwork and only need a small number of shirts (less than 24). HEAT TRANSFERS are sometimes a more cost-effective solution.

PRINTING METHODS & INK OPTIONS

Premium Plastisol

Plastisol inks are plastic-based and are the most versatile inks used in screen printing. This ink sits ON TOP of the fabric, creating a feeling that can be modified for a super soft hand or made to have a heavy hand depending on the desired effect. These phthalate-free inks can be printed on cotton, polyester & blended fabrics. We use Wilflex Epic Rio for all our premium plastisol needs.

Metallic Ink

Metallic ink is a specialty plastisol ink that has tiny metallic flakes in it. When printed, this ink creates an eye-catching, shimmery finish. Metallic inks look best as an accent to design because the metallic flake additive makes for a thicker hand and is slightly stiffer than standard plastisols.

Glitter Ink

Glitter ink is a specialty plastisol ink that has metallic flakes of glitter in it. When printed, this ink creates an eye-catching, glitter finish. Glitter inks look great as an accent to design because the glitter flake additive makes for a thicker hand and is slightly stiffer than standard plastisols or across the entire design for an eye-catching statement. We offer up to 11 glitter color options that can work for schools, sports, organizations, and more.

Glow in the Dark Ink

Glow in the dark inks are a type of specialty plastisol ink used for enhancing a design that needs to be seen at night or in the dark. We offer 11 daylight ink colors with 11 glow color options that create a unique special effect for your design.

Puff Ink

Puff is a plastisol ink that has a puff additive, which makes the ink rise up on the shirt with a foamy, puffy feel when heat cured. This fantastic option allows you to produce an eye-catching 3D texture. We recommend using this technique as an accent or embellishment to add a pop to your T-shirt design.

Foil

Create attention-getting designs using custom foil options. Add a metallic finish for a fashionable effect to any garment or design. This technique works perfectly for isolating a specific element and accenting it with some bling!

Special Effect Ink

SFX, or Special Effects Screen Printing Inks, come in a variety of styles and colors. These inks are used to exaggerate an element, focal point, or effect in a design. They are printed with simulated process print methods which can be modified to achieve virtually any type of desired outcome like an eroded or shattered distressing effect, 3D raised print, and textures such as faux leather.

STANDARD PRINT LOCATIONS

Full Front

Full Back

Left & Right Chest

BACK YOKE

SPECIALTY PRINT LOCATIONS

Bottom of Shirt

SIDES

SLEEVES

SHOULDERS

STANDARD IMPRINT SIZES

FRONT/BACK

12″ Wide x 14″ Tall

LEFT & RIGHT CHEST

3.5″ Wide x 3.5″ Tall

SLEEVES

3.25″ Wide x 4″ Tall

MAX IMPRINT SIZES

SLEEVES (LONG SLEEVES)

3.25″ Wide x 16″ Tall

FRONT/BACK

15″ Wide x 18″ Tall

FAQ

Do you have a minimum order size?

No, we can print as few as 1 shirt up to 100,000 pieces plus. We have a custom solution to fit every project, big or small.

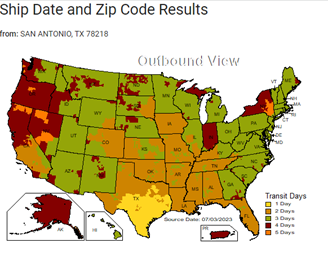

What is your turnaround time for screen printing?

Our normal production time for screen printing is 5-7 business Days from the date of art approval and all merchandise must be received in-house.

We can accommodate rush orders for projects with lead times less than our 5-day turnaround, however a rush fee may apply depending on our current workflow. Rush services require approval from the customer service department. (Taking longer than 24 hours to approve your digital proofs may delay your order.)

Can you provide RUSH services?

Yes! We can accommodate rush orders for projects with lead times less than our 5-day turnaround, however a rush fee may apply depending on our current workflow. Rush services require approval from the customer service department. (Taking longer than 24 hours to approve your digital proofs may delay your order.)

What are spoilage or underruns?

In custom manufacturing, such as screen printing customer supplied goods, minor fluctuations in the final number of units produced against the exact quantity ordered can occur. At Screen Pro Graphics, all orders can have up to 2% spoilage allowance or underrun. This accounts for manufacturer defects such as snags, stains, holes or damaged goods. Additionally, minimal damages or misprints can occur during any mass production processes. Due to the nature of this business, we cannot be held responsible for shortages under the 2% threshold. The decoration cost for all damages or defects are credited upon invoicing. We recommend ordering extra goods if your project requires exact quantities. We have the capability of returning unprinted extras to the supplier, if necessary. Among promotional product suppliers, the industry standard for overruns and underruns allows for a + or – 5% discrepancy, which our 2% policy is well under.

What type of art files do you need for screen printing?

Preferred vector file types include these formats: AI, EPS, or PDF. Photographs should be provided in one of the following formats: PSD, TIF, EPS, PNG or JPG. We cannot begin an order until we have usable artwork. All files must be a minimum of 300 dpi for images or a vector file for designs. Once received, our in-house art department will take care of prepping the art for printing. You will receive an email with a link to a digital art proof for approval prior to Screen Pro Graphics proceeding with production.

Are your inks Phthalate free?

Yes! As an environmentally conscientious company, we have chosen to align ourselves with WilflexTM Epic Rio brand inks, the leading manufacturer of plastisol-based ink in the screen printing industry. These inks are the most advanced non-phthalate plastisol inks that conform to all shipping regulations nationwide.

What is underbase in screen printing?

Most T-shirts ordered for screen printing are darks or colors and many designs call for bright colors that pop off the shirt. Since most Plastisol inks are semi-transparent, simply putting down one layer of ink can cause the color to look dull and washed out on darks and can change the hue of the ink on colors. To ensure the vibrancy and color correctness of the ink, we use an underbase (or underlay) where we print a layer of high-opacity white ink on the garment and flash-cure it before the other colors are printed. This can be compared to priming a wall before you paint it the color of your choice.

Why underbase?

Screen Pro Graphics uses this technique for several reasons:

First, we use an underbase on all colored garments for the best quality imprint colors and pigments. Printing and flash-curing a white base ensures the overall vibrancy of the imprint.

Second, the use of an underbase ensures color accuracy. Printing on top of a white underbase mostly eliminates the color of the shirt affecting the ink colors chosen for the design. This is especially important when matching specific logo standards or color requests using the Pantone Matching System (PMS) colors.

Third, we use a base to reduce fibrillation. The underbase creates a smooth surface for the ink to sit on top of, rather than having fuzzy shirt fibers poking through and giving the imprint a grainy look.

What is a color change?

A color change occurs when the same screens can be used for multiple colorways. For example, if you had a design where you wanted a blue imprint on a white shirt, and an orange imprint on a yellow shirt, we would remove the blue ink and replace it with orange using the same screen.

We encourage you to let us know how we can help you bring your vision to life. Whether through our unique specialty ink options, in-house creative art department, or top-quality screen-printing production, our world-class customer service team is here to guide you to the perfect custom printing solution. The better you express your overall vision and goal of the finished garment and how you would like the print to look and feel, the better we can fulfill or exceed your expectations. We encourage your input, so we know what you and your client(s) want to achieve in order to deliver 100% customer satisfaction.